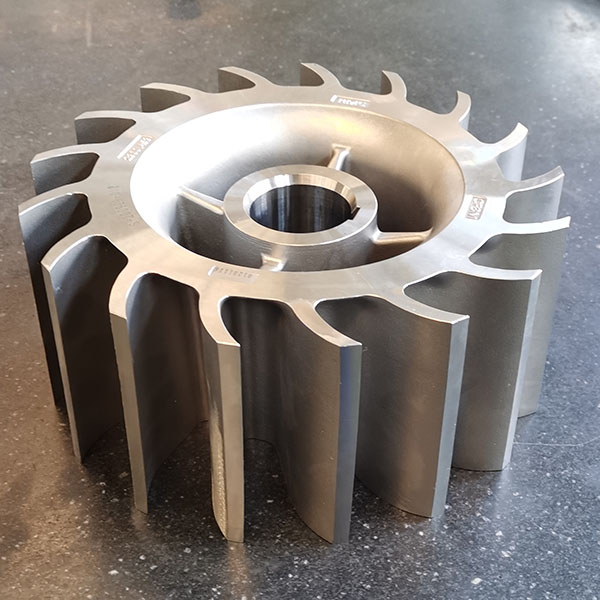

OEM consuetudo duplex 2205/1.4462 iactatio ferri immaculata cum CNC machinis machinis Sinaruminvestment mittentes liquatur.

Duplex 2205 ferrum intemeratum fundenssignificat fusuras Duplex ferro immaculatam.Duplex Steel (DSS) refertur ad chalybem immaculatum cum ferrite et austenite utriusque rationis circiter 50%.Fere, contentum graduum minorum saltem 30% esse debet.In rebus humilibus C contentum, Cr contentus est 18% ad 28%, et Ni contentus est 3% ad 10%.Duplex quidam chalybeis immaculatus etiam elementa mixturae continent, ut Mo, Cu, Nb, Ti, N.

DSS characteres austenitici et ferritici ferri immaculati habet.Comparatus cum ferrite, altiorem plasticitatem et ductilis habet, nullum cella temperaturae fragilitas, et intergranulares corrosio resistentia et glutino effectus signanter emendavit, servato adhuc fragilitate, magna conductivity scelerisque, et super materia plastica sicut ferrite immaculatam ferrum.Comparatus cum austenitico chalybe immaculato, DSS altam vim habet et signanter resistentiam ad corrosionem intergranularem et chlorideum accentus corrosionem habet.Duplex immaculatus ferroPraeclaram pituitae corrosionis resistentiam habet et etiam nickel-salutat ferro immaculato.

| Materiae forProcessus investment Iactisapud RMC *

| |||

| Categoria | Sina Gradus | US Gradus | Germania Grade |

| Ferritic Steel | 1Cr17, 022Cr12, 10Cr17; | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| Martensitic Steel | 1Cr13, 2Cr13, 3Cr13, 4Cr13; | 410, 420, 430, 440B, 440C . | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125. |

| Austenitic immaculatam ferro | 06Cr19Ni10, 022Cr19Ni10; 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 | 302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.4406, 1.4408, 1.4409, 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581; 1.4582, 1.4584; |

| Praecipitatio Hardening Diver | 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 |

| Duplex Steel | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A; A 995 1B, A 995 4A, A 995 5A, 2205, 2507 | 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 |

| Princeps Mn Steel | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Instrumentum Steel | Cr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Calor resistens Steel | 20Cr25Ni20, 16Cr23Ni13; 45Cr14Ni14W2Mo | 309, 310, CK 20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| Nickle-basi Alloy | PRAECEL-C, PRAECEL-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX(66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35. -1, INCOLOY600; INCOLOY625 | 2.4815, 2.4879, 2.4680 | |

| aluminium Alloy | ZL101, ZL102, ZL104 | ASTM A356, ASTM A413, ASTM A360 | G-AlSi7Mg, G-Al12 |

| Aeris Alloy | H96, H85, HPb63-3; HPb59-1, QSn6.5-0.1, QSn7-0.2 | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 | CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5 |

| Cobaltum basi Alloy | UMC50, 670, Grade 31 | 2.4778 | |