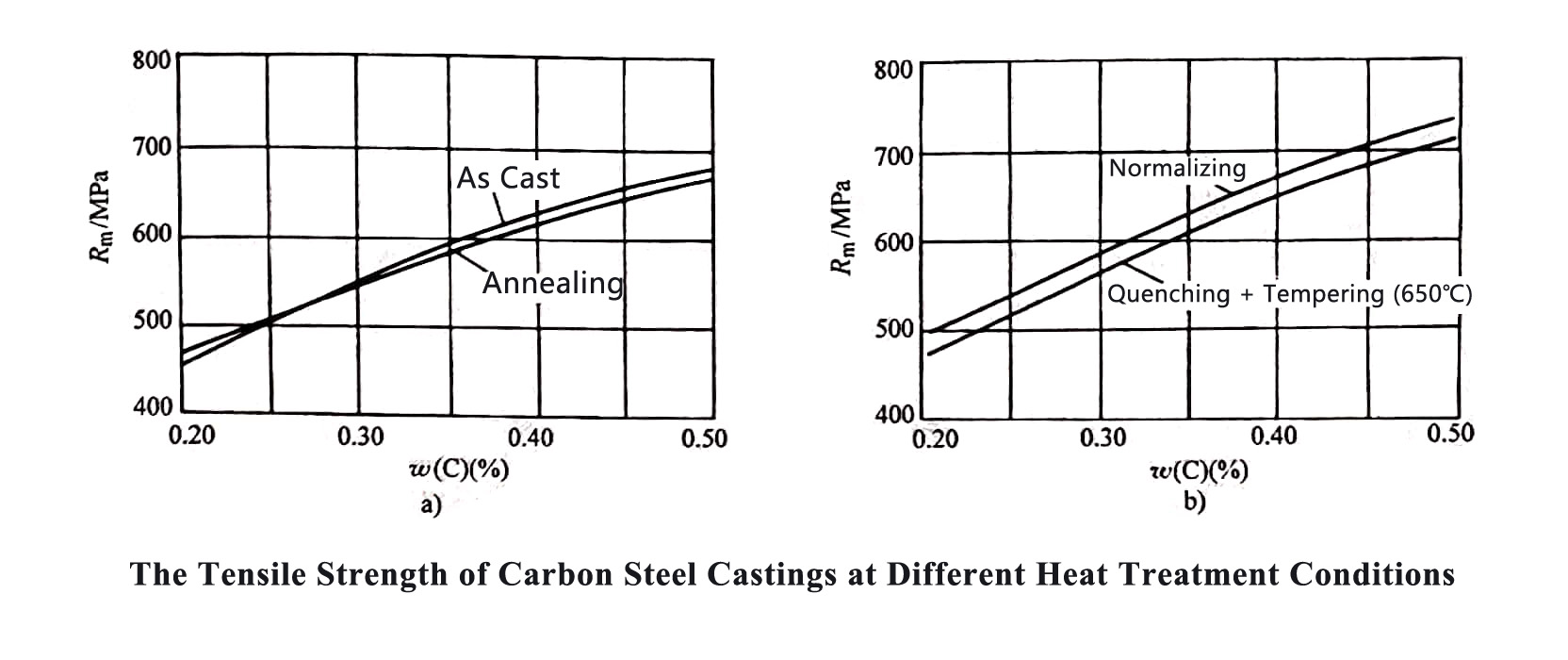

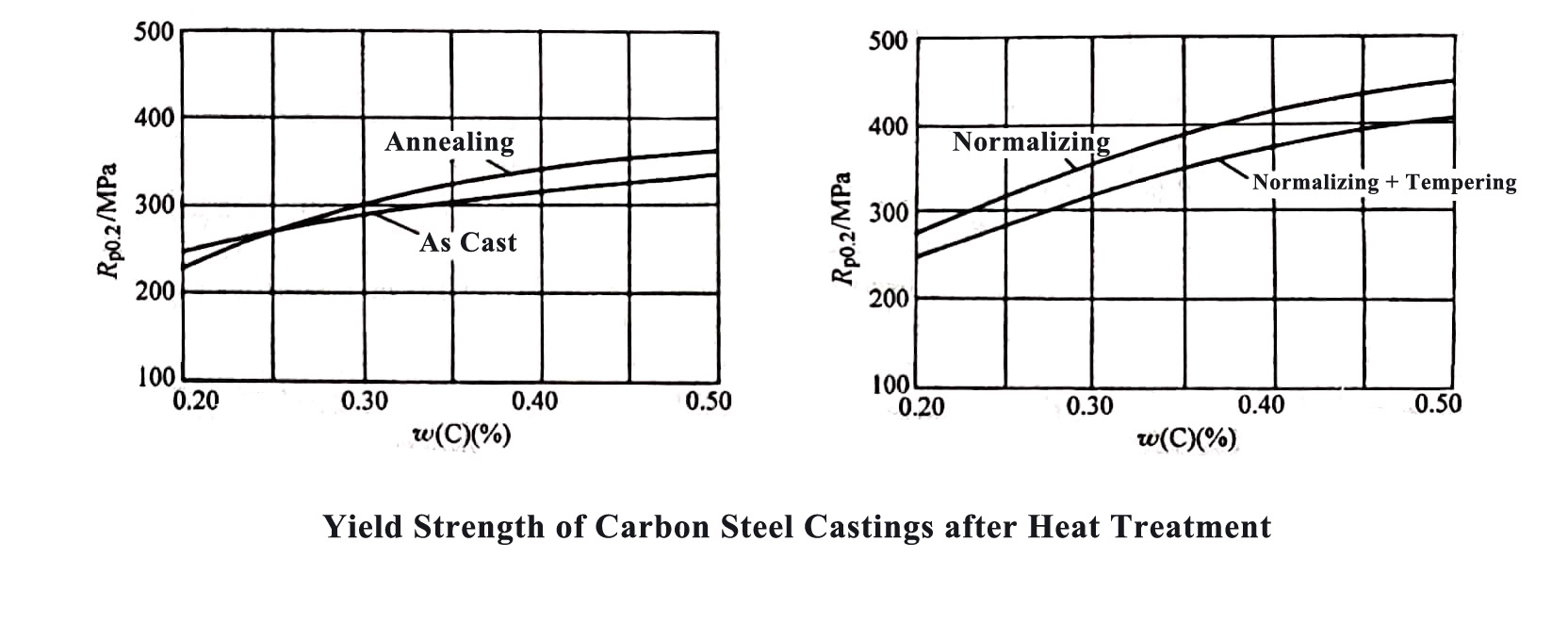

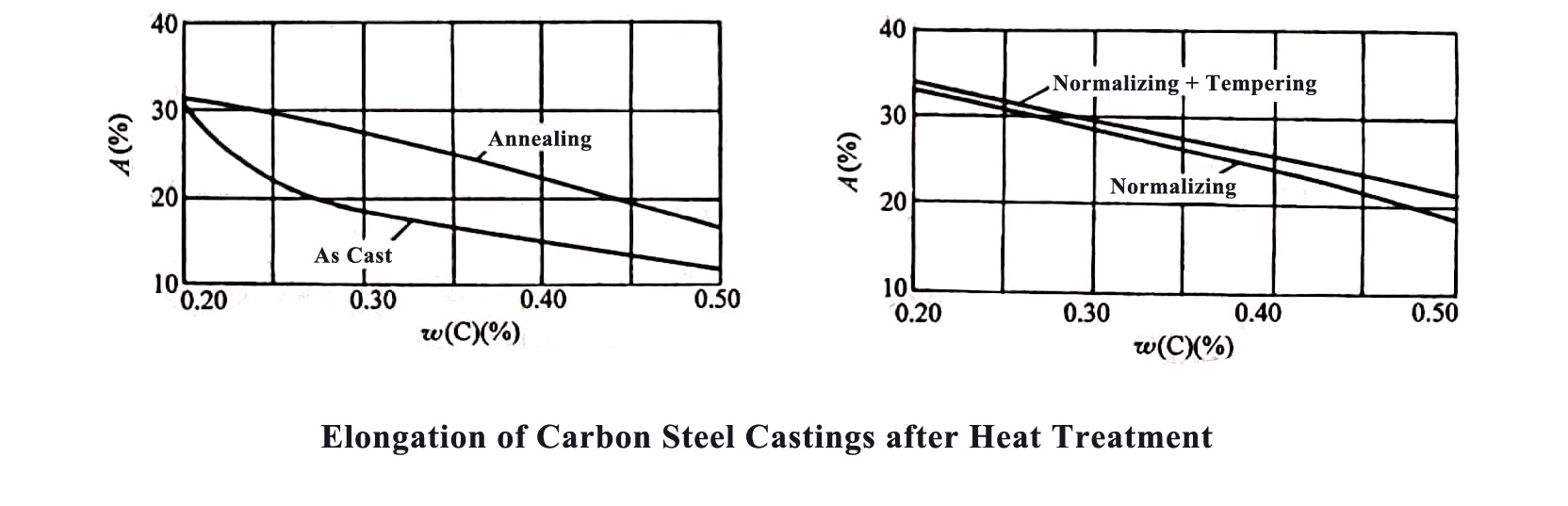

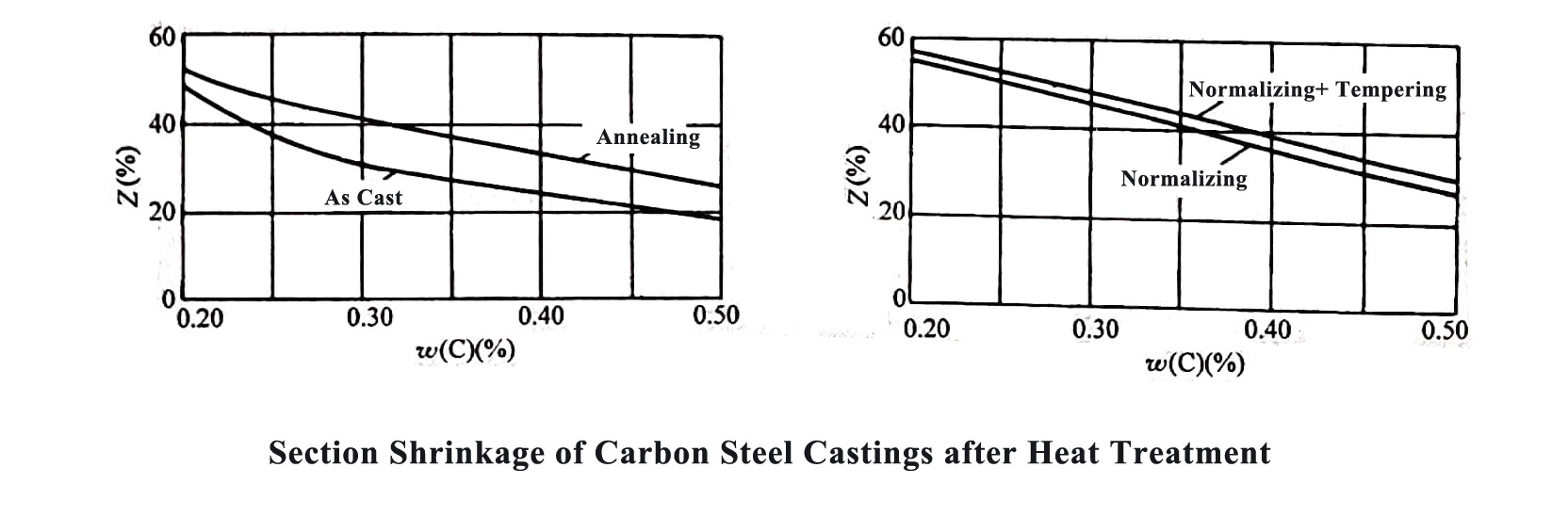

Modi curationis caloris usi sunt pro fundis chalybis carbonis sunt: furnum, normalisandi vel temperandi + temperandi. Influentia horum trium curationum caloris methodi in proprietatibus mechanicis de chalybe carbonis in figura infra ostendetur.

| Annealing Temperature et Duritie Carbonis Steel Castings | ||||||

| Gradus Carbonis Steel | Carbon Content / % | Annealing Temperature / | Tenens Tempus | Refrigerationem Methodo | duritia / HBW | |

| Murus Crassitudo / mm | Tempus / h | |||||

| ZG200 - 400 | 0.10 - 0.20 | 910 - 880 | 30 | 1 | 620℃ refrigeratio in fornacibus et refrigeratio in aere | 115 - 143 |

| ZG230 - 450 | 0.20 - 0.30 | 900 - 870 | 133 - 156 | |||

| ZG270 - 500 | 0.30 - 0.40 | 890 - 860 | 143 - 187 | |||

| ZG310 - 570 | 0.40 - 0.50 | 870 - 840 | 30 - 100 | auget I hora / XXX mm | 156 - 127 | |

| ZG340 - 640 | 0.50 - 0.60 | 860 - 830 | 187 - 230 | |||

Mechanica proprietas de ferro iacto normalized paulo altiores sunt quam ferrum annatae emissum. Sicut gradus undercooling in transformatione structurae relative magna est, durities altior erit, et melius incisio fit.

| Normalisandi et duritiem Carbon Steel Castings | |||||

| Gradus Carbonis Steel | Carbon Content (%) | Temperature normalizing / | Temperatio | duritia / HBW | |

| Temperatus / | Refrigerationem Methodo | ||||

| ZG200 - 400 | 0.10 - 0.20 | 930 - 890 | 540 - 610 | in fornacem vel aer | 126 - 149 |

| ZG230 - 450 | 0.20 - 0.30 | 930 - 890 | 540 - 610 | in fornacem vel aer | 139 - 169 |

| ZG270 - 500 | 0.30 - 0.40 | 890 - 860 | 550 - 620 | in fornacem vel aer | 149 - 187 |

| ZG310 - 570 | 0.40 - 0.50 | 890 - 850 | 550 - 650 | in fornacem vel aer | 163 - 217 |

| ZG340 - 640 | 0.50 - 0.60 | 870 - 830 | 550 - 650 | in fornacem vel aer | 187 - 228 |

Pro chalybeis iactationibus magnis carbonis contentis et formis implicatis, ad tollendam residuas accentus et duritiem meliores, curatio temperantia peragi potest post normalizationem. Temperatura temperatura plerumque 550℃-650℃ est, et tunc in aere refrigescit.

Cum carbonis contentum altior est quam 0,35%, partes ferri carbonis conflatae etiam extingui et temperari possunt (exstinguitur + caliditas temperata). Parvae ferri carbonis fusurae directe extingui et temperari in statu as-casto possunt; magnae vel implicatae carbonis chalybeis iactationes exstinguendae et temperandae iuxta normalizationem.

| Exstingui et Temperature Temperature et Duritie Carbonis Ferri Castings | |||

| Carbon Content % | Exstingui Temperature / | Temperature Temperature / | Duritia post temperationem / HBW |

| 0.35 - 0.45 (Parvus Batch) | 850 - 830 (Frigus in Aqua) | 300 - 400 | 364 - 444 |

| 400 - 450 | 321 - 415 | ||

| 510 - 550 | 241 - 286 | ||

| 540 - 580 | 228 - 269 | ||

| 580 - 640 | 192 - 228 | ||

| 0.45 - 0.55 (Parvus Batch) | 830 - 810 (in aqua vel oleo refrigeratum) | 550 - 630 | 220 - 240 |

| 450 | ≈ 269 | ||

| 550 | ≈ 248 | ||

| 650 | ≈ 228 | ||

| 0.30 - 0.40 (Missa Batch) | 840 -880 (in aqua vel oleo refrigeratum) | 520 - 550 | 229 - 269 |

| 530 - 560 | 217 - 255 | ||

| 540 - 570 | 207 - 241 | ||

| 550 - 580 | 187 - 229 | ||

| 0.40 - 0.50 (Missa Batch) | 820 - 840 (in aqua vel oleo refrigeratum) | 530 - 560 | 229 - 269 |

| 550 - 580 | 217 - 255 | ||

| 560 - 590 | 207 - 241 | ||

| 570 - 600 | 187 - 229 | ||

Post tempus: Iul-23-2021