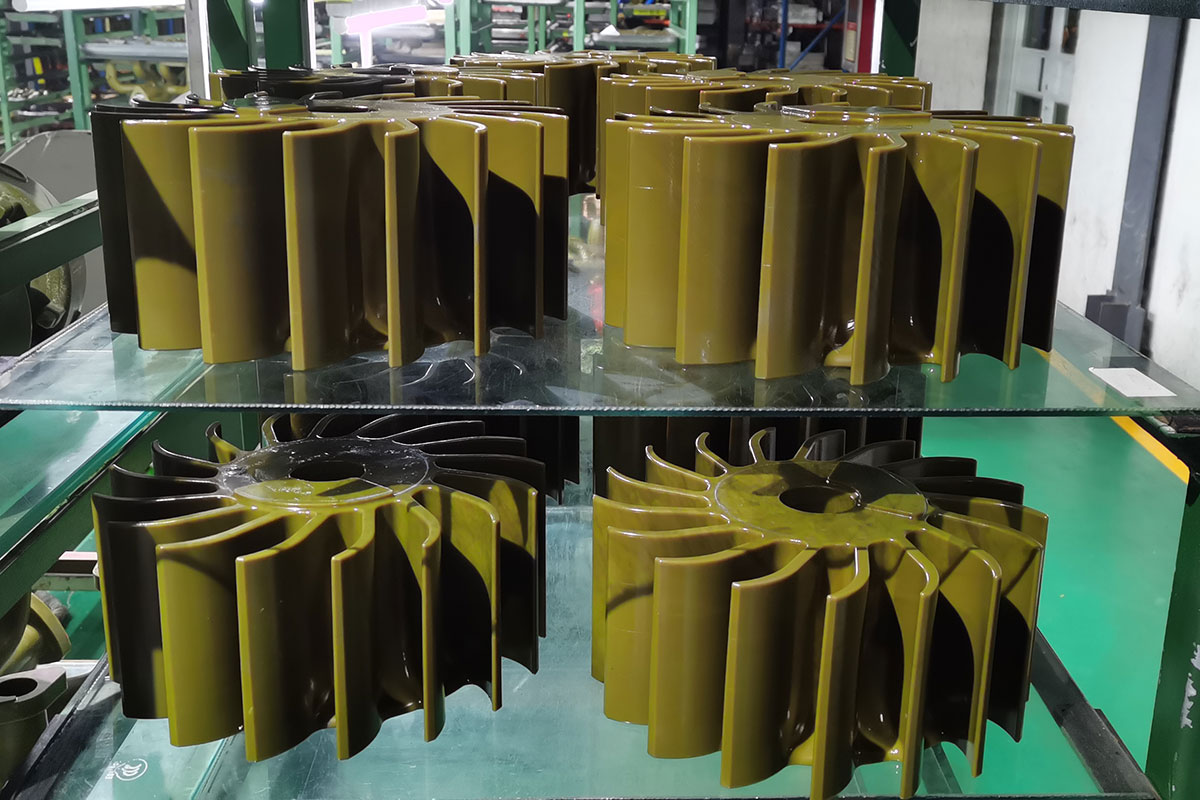

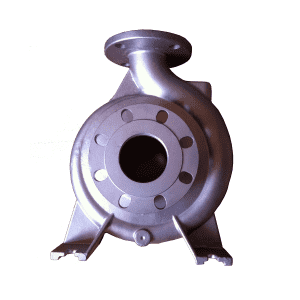

Sina OEM consuetudo immaculata ferro impulsoramissa cera obsideri mittentes processus.

Basis offensionis elementa cuiusvis nickel-basis vel inactae ferro dejectae sunt chromium, nickel, et molybdenum (vel "moly").Haec tria constituent structuram frumenti et proprietates mechanicas abiectionis et instrumentales in facultate pugnandi caloris, indumenti et corrosionis.

Chalybs immaculata minimum chromium contentum 10.5% habet, eoque magis resistit ad ambitus liquidi corrosivi et oxidationis.Sed hoc non est absolutum.Aliquam ferro investmentfusurae sunt "corrosio-resistentes" cum in ambitibus liquidis et vaporibus adhibitis infra 1200°F (650°C) et "aestus repugnans" cum supra hanc temperiem adhibitus est.

Commoda Investment Iactandi Components:

- Superficies optima et lenis meta

- Stricta tolerantiae dimensiva.

- Complexae et intricatae figurae cum consilio flexibilitate

- Facultas igitur tenuiores ejiciendi parietes tenues component

- Lata selectio metallica et admixtionum (ferrarum et non-ferrarum)

— Draft in fingit consilio non requiritur.

- Reducere necessitatem machinis secundae.

— Humilis materia perditio.

| Materiae forInvestment IactareProcessus atRMC Foundry | |||

| Categoria | Sina Gradus | US Gradus | Germania Grade |

| Ferritic Steel | 1Cr17, 022Cr12, 10Cr17; | 430, 431, 446, CA-15, CA6N, CA6NM | 1.4000, 1.4005, 1.4008, 1.4016, GX22CrNi17, GX4CrNi13-4 |

| Martensitic Steel | 1Cr13, 2Cr13, 3Cr13, 4Cr13; | 410, 420, 430, 440B, 440C . | 1.4021, 1.4027, 1.4028, 1.4057, 1.4059, 1.4104, 1.4112, 1.4116, 1.4120, 1.4122, 1.4125. |

| Austenitic immaculatam ferro | 06Cr19Ni10, 022Cr19Ni10; 06Cr25Ni20, 022Cr17Ni12Mo2, 03Cr18Ni16Mo5 | 302, 303, 304, 304L, 316, 316L, 329, CF3, CF3M, CF8, CF8M, CN7M, CN3MN | 1.3960, 1.4301, 1.4305, 1.4306, 1.4308, 1.4313, 1.4321, 1.4401, 1.4403, 1.4404, 1.4405, 1.4406, 1.4408, 1.4409, 1.4435, 1.4436, 1.4539, 1.4550, 1.4552, 1.4581; 1.4582, 1.4584; |

| Praecipitatio Hardening Diver | 05Cr15Ni5Cu4Nb, 05Cr17Ni4Cu4Nb | 630, 634, 17-4PH, 15-5PH, CB7Cu-1 | 1.4542 |

| Duplex Steel | 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N | A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A; A 995 1B, A 995 4A, A 995 5A, 2205, 2507 | 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770 |

| Princeps Mn Steel | ZGMn13-1, ZGMn13-3, ZGMn13-5 | B2, B3, B4 | 1.3802, 1.3966, 1.3301, 1.3302 |

| Instrumentum Steel | Cr12 | A5, H12, S5 | 1.2344, 1.3343, 1.4528, GXCrMo17, X210Cr13, GX162CrMoV12 |

| Calor resistens Steel | 20Cr25Ni20, 16Cr23Ni13; 45Cr14Ni14W2Mo | 309, 310, CK 20, CH20, HK30 | 1.4826, 1.4828, 1.4855, 1.4865 |

| Nickle-basi Alloy | PRAECEL-C, PRAECEL-X, SUPPER22H, CW-2M, CW-6M, CW-12MW, CX-2MW, HX(66Ni-17Cr), MRE-2, NA-22H, NW-22, M30C, M-35. -1, INCOLOY600; INCOLOY625 | 2.4815, 2.4879, 2.4680 | |

| aluminium Alloy | ZL101, ZL102, ZL104 | ASTM A356, ASTM A413, ASTM A360 | G-AlSi7Mg, G-Al12 |

| Aeris Alloy | H96, H85, HPb63-3; HPb59-1, QSn6.5-0.1, QSn7-0.2 | C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100 | CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5 |

| Cobaltum basi Alloy | UMC50, 670, Grade 31 | 2.4778 | |

| INVESTMENT IACTATIO TOLERATIO | |||

| Unciarum | Millimeters | ||

| Dimension | tolerantia | Dimension | tolerantia |

| Ad 0.500 | ±.004" | Ad 12.0 | ± 0.10mm |

| 0.500 ad 1.000" | ±.006" | 12.0 ad 25.0 | ± 0.15mm |

| 1.000 ad 1.500" | ±.008" | 25.0 ad 37.0 | ± 0.20mm |

| 1.500 ad 2.000" | ±.010" | 37.0 ad 50.0 | ± 0.25mm |

| 2.000 ad 2.500" | ±.012" | 50.0 ad 62.0 | ± 0.30mm |

| 2.500 ad 3.500" | ±.014" | 62.0 ad 87.0 | ± 0.35mm |

| 3.500 ad 5.000" | ±.017" | 87.0 ad 125.0 | ± 0.40mm |

| 5.000 ad 7.500" | ±.020" | 125.0 to190.0 | ± 0.50mm |

| 7.500 ad 10.000" | ±.022" | 190.0 ad 250.0 | ± 0.57mm |

| 10.000 ad 12.500" | ±.025" | 250.0 ad 312.0 | ± 0.60mm |

| 12.500 ad 15.000 | ±.028" | 312.0 ad 375.0 | ± 0.70mm |