Consuetudo valvae habitationum duarum immacularum ferro productarum ab obsidione dejectis e Sinis fundamentis fundentismachiningcuratio caloris, et curatio superficiei officia.

RMC castsubtilitas ferro partesconstanter occurrit vel excedens elit exspectationes.Amissa cera investment mittentes nos sinit producereimmaculatam ferro mittentes productsminora quam decem P. * et totidem chiliogrammata, in amplis admixtionibus ferreis et non ferreis, ac singulari subtilitate dimensionis.

Amissae cerae in obsidione mittentes processus producit ad instar reticuli subtilitatem iecturae quae saepe parum vel nullas machinis additas requirit.Consequens absolutio multo etiam melius est quam id quod per alios dejectiones vel processus fabricandi effici potest.Robur et durabilitas partium emissionum se specimen faciunt ad applicationes magno labore resistentiae, quae decies centena milia cyclorum requirunt.

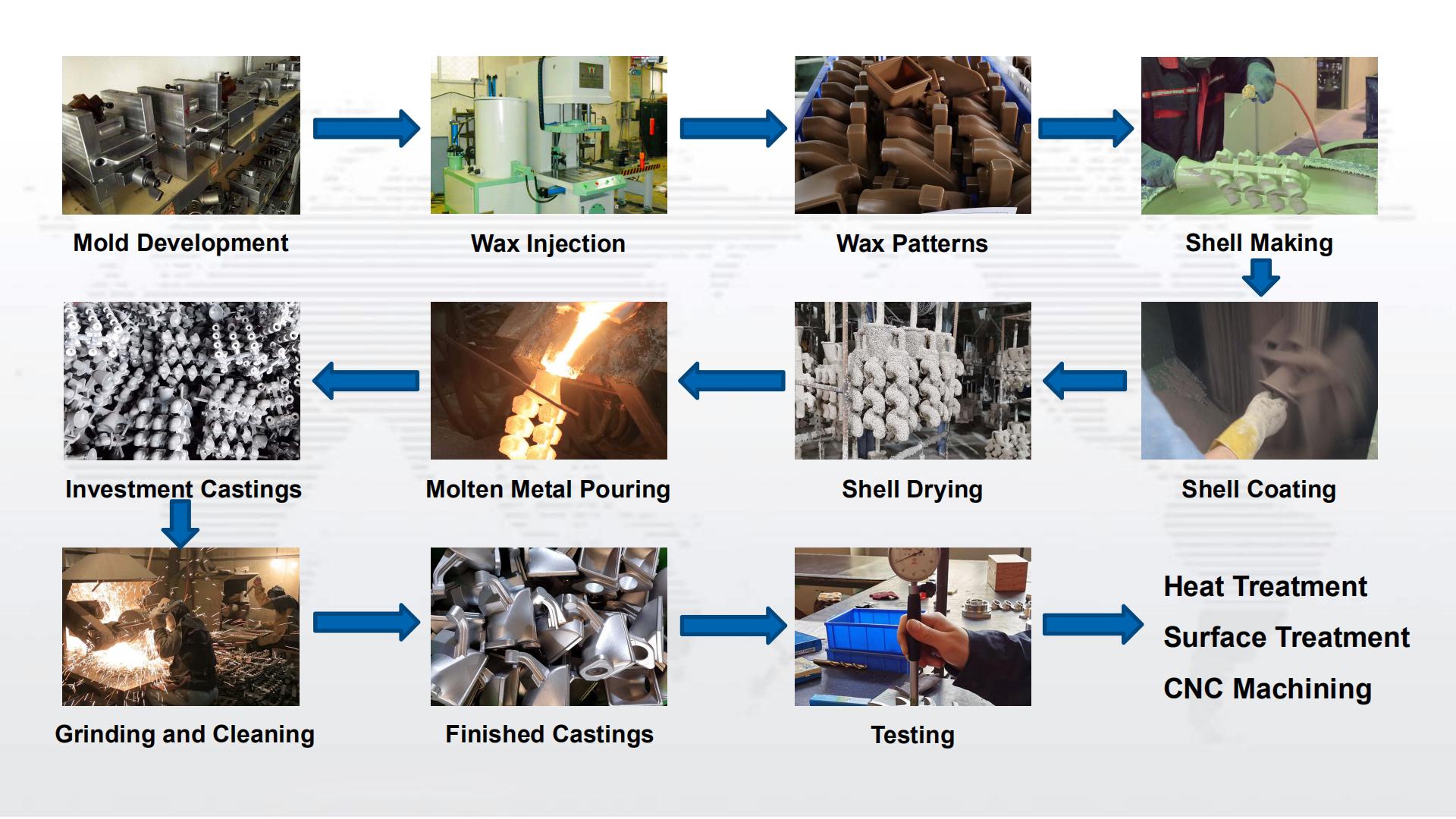

Gradus elit mittentes processus:

In processu collocationis mittentes, forma ceramica materia ceramica obducta est, quae, indurata, geometriam internum desideratae iectionis adoptat.Pleraque in plures partes coniciuntur ad efficaciam altam, applicando singula exemplaria cerae ad medium cerae lignum, quod vocatur abiegna.Cera liquescit ex exemplari - unde etiam cognoscitur sicut processus cerae amissae - et conflatile in cavum infunditur.Cum metallum solidatur, forma ceramica discutitur, relinquens formam prope rete desideratae iactus, peractam, tentans et packing.

Duplex Steel (DSS) refertur ad chalybem immaculatum cum ferrite et austenite utriusque rationis circiter 50%.Fere, contentum graduum minorum saltem 30% esse debet.In rebus humilibus C contentum, Cr contentus est 18% ad 28%, et Ni contentus est 3% ad 10%.Duplex quidam chalybeis immaculatus etiam elementa mixturae continent, ut Mo, Cu, Nb, Ti, N.

Praesto gradus duplex ferro incorrupto in RMC Fundi fundentis: 1.4460, 1.4462, 1.4468, 1.4469, 1.4517, 1.4770, A 890 1C, A 890 1A, A 890 3A, A 890 4A, A 890 5A, A 995 1B, A 995 4A , A 995 5A, 2205, 2507, 022Cr22Ni5Mo3N, 022Cr25Ni6Mo2N

DSS characteres austenitici et ferritici ferri immaculati habet.Comparatus cum ferrite, habet altiorem plasticitatem et ductilem, nullum cella temperaturae fragilitas, et intergranulare corrosio resistentia et glutino effectus signanter emendavit, servato adhuc fragilitate, magna conductivity scelerisque, et superplasticitate sicut ferrite immaculatam ferrum.Comparatus cum austenitico chalybe immaculato, DSS altam vim habet et signanter resistentiam ad corrosionem intergranularem et chlorideum accentus corrosionem habet.Duplex chalybs immaculata egregiam fovens corrosionem habet resistentiam et etiam nickel-salvam chalybem immaculatam habet.

| Equivalent Grade de Diver | |||||||

| GROUPS | AISI | W-stoff | DIN | BS | SS | UNE/IHA | UNI |

| Martensitic et Ferritic Steel | 420 C | 1,404 | X43Cr16 | ||||

| 440 B/1 | 1,4112 | X90 Cr Mo V18 | |||||

| - | 1.2083 | X42 Cr 13 | - | 2314 | F.5263 | - | |

| 403 | 1.4000 | X6Cr13 | 403 S 17 | 2301 | F.3110 | X6Cr13 | |

| (410S) | 1.4001 | X7 Cr 14 | (403 S17) | 2301 | F.3110 | X6Cr13 | |

| 405 | 1.4002 | X6 CrAl 13 | 405 S 17 | - | F.3111 | X6 CrAl 13 | |

| 416 | 1.4005 | X12 CrS 13 | 416 S 21 | 2380 | F.3411 | X12CrS13 | |

| 410 | 1.4006 | X 10 Cr 13 | 410 S21 | 2302 | F.3401 | X12Cr13 | |

| 430 | 1.4016 | X6 Cr 17 | 430 S 17 | 2320 | F.3113 | X8Cr17 | |

| 420 | 1.4021 | X20 Cr 13 | 420 S 37 | 2303 | F.3402 | X20Cr13 | |

| 420F | 1.4028 | X30 Cr 13 | 420 S 45 | (2304) | F.3403 | X30Cr13 | |

| (420) | 1.4031 | X39Cr13 | 420 S 45 | (2304) | F.3404 | - | |

| 431 | 1.4057 | X20 CrNi 17 2 | 431 S 29 | 2321 | F.3427 | X16CrNi16 | |

| 430F | 1.4104 | X12 CrMoS 17 | - | 2383 | F.3117 | X10CrS17 | |

| 434 | 1.4113 | X6 CrMo 17 | 434 S 17 | 2325 | - | X8CrMo17 | |

| 430Ti | 1.4510 | X6 CrTi 17 | - | - | - | X6CrTi17 | |

| 409 | 1.4512 | X5 CrTi 12 | 409 S 17 | - | - | X6CrTi12 | |

| Austenitic Steel | 304 | 1.4301 | X5 CrNi 18 9 | 304 S 15 | 2332 | F.3551 | X5CrNi18 10 |

| 305 | 1.4303 | X5 CrNi 18 12 | 305 S 19 | - | - | X8CrNi19 10 | |

| 303 | 1.4305 | X12 CrNiS 18 8 | 303 S 21 | 2346 | F.3508 | X10CrNiS 18 09 | |

| 304L | 1.4306 | X2 CrNiS 18 9 | 304 S 12 | 2352 | F.3503 | X2CrNi18 11 | |

| 301 | 1.4310 | X12 CrNi 17 7 | - | 2331 | F.3517 | X12CrNi17 07 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S 31 | 2332 | F.3551 | X5CrNi18 10 | |

| 304 | 1.4350 | X5 CrNi 18 9 | 304 S 31 | 2333 | F.3551 | X5CrNi18 10 | |

| 304LN | 1.4311 | X2 CrNiN 18 10 | 304 S 62 | 2371 | - | - | |

| 316 | 1.4401 | X5 CrNiMo 18 10 | 316 S 16 | 2347 | F.3543 | X5CrNiMo17 12 | |

| 316L | 1.4404 | - | 316 S 12/13/14/22/24 | 2348 | X2CrNiMo17 12 | ||

| 316LN | 1.4429 | X2 CrNiMoN 18 13 | - | 2375 | - | - | |

| 316L | 1.4435 | X2 CrNiMo 18 12 | 316 S 12/13/14/22/24 | 2353 | - | X2CrNiMo17 12 | |

| 316 | 1.4436 | - | 316 S 33 | 2343 | - | X8CrNiMo 17 13 | |

| 317L | 1.4438 | X2 CrNiMo 18 16 | 317 S 12 | 2367 | - | X2CrNiMo18 16 | |

| 329 | 1.4460 | X3 CrNiMoN 27 5 2 | - | 2324 | F.3309 | - | |

| 321 | 1.4541 | X10 CrNiTi 18 9 | 321 S 12 | 2337 | F.3553 | X6CrNiTi18 11 | |

| 347 | 1.4550 | X10 CrNiNb 18 9 | 347 S 17 | 2338 | F.3552 | X6CrNiNb18 11 | |

| 316Ti | 1.4571 | X10 CrNiMoTi 18 10 | 320 S 17 | 2350 | F.3535 | X6CrNiMoTi 17 12 | |

| 309 | 1.4828 | X15 CrNiSi 20 12 | 309 S 24 | - | - | X16 CrNi 24 14 | |

| 330 | 1.4864 | X12 NiCrSi 36 16 | - | - | - | - | |

| Duplex Steel | S32750 | 1.4410 | X 2 CrNiMoN 25 7 4 | - | 2328 | - | - |

| S31500 | 1.4417 | X 2 CrNiMoSi 19 5 | - | 2376 | - | - | |

| S31803 | 1.4462 | X 2 CrNiMoN 22 5 3 | - | 2377 | - | - | |

| S32760 | 1.4501 | X 3 CrNiMoN 25 7 | - | - | - | - | |

| 630 | 1.4542 | X5CrNiCNb16-4 | - | - | - | - | |

| A564/630 | - | - | - | - | - | - | |

Ferrous Metals and Non ferreus Metalla forInvestment Iactare, Cera Iactis Processu perdita:

• Gray Iron: HT150, HT200, HT250, HT300, HT350;GJL-C, GJL-CL, GJL-CC, GJL-CCL, GJL-CCC, GJL-CCCL;GG10~ GG40.

• Ferrum ductile seu ferrum nodulare: GGG40, GGG50, GGG60, GGG70, GGG80;GJS-400-18, GJS-40-15, GJS-450-10, GJS-D-VII, GJS-DC-III, GJS-700-2, GJS-DCCC-II;QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

• Carbon Steel: AISI 1020 - AISI 1060, C30, C40, C45.

• Steel Alloys: ZG20SiMn, ZG30SiMn, ZG30CrMo, ZG35CrMo, ZG35SiMn, ZG35CrMnSi, ZG40Mn, ZG40Cr, ZG42Cr, ZG42CrMo...etc.

• Steel: AISI 304, AISI 304L, AISI 316, AISI 316L, 1.4401, 1.4301, 1.4305, 1.4307, 1.4404, 1.4571 et alii gradus intemerate ferro.

• aes, rubrum cuprum, aeneum vel alia metalla aeris substructio mixturae: ZCuZn39Pb3, ZCuZn39Pb2, ZCuZn38Mn2Pb2, ZCuZn40Pb2, ZCuZn16Si4

• Aliae materias ut per singularia tua requisita vel secundum ASTM, SAE, AISI, ACI, DIN, EN, ISO, GB signa

Facultates ofInvestment mittentes aliquet pretium

• Max Size: 1,000 mm × 800 mm × 500 mm

• Pondus dolor: 0.5 kg - 100 kg

• Capacitas annui: 2,000 tons

• Materiae vinculi ad Testam Aedificium: Silica Sol, Vitrum Aquarum et earum mixtiones.

| Officia | Descriptio |

| Superficiem Curatio Services | Pulvis Coating, Anodization, Electrophotesis, Chrome Plating, Pictura, Sand urente, Nickel Plating, Zinc Plating, Blacking, Politura, Bluing, Geormet, Zintek, etc. |

| CNC Precision Machining Services | Lathing, Milling, Convertere, Honing, EXERCITATIO, Boring, Tapping, Filum Electrode Secans, Molendum...etc. |

| Inspectio et Qualitas Imperium | Spectrum Analyzer, CMM, Hardness Tester, Tendens robur Tester, Yild Strentgh Testor, Obsignatio Pressure Tester, Carbon Sulfur Analyser, Metallurgical Microscopia, Press Force Tester...etc. |