OEM consuetudo aes eiectum LABIUM et alia locatio- nem aeneam mittentem magni ponderis partes habent ut frutices, anni, valvae et sentinae corpora, aquae fistulae et alia.mechanica ndustriesquibus opus est perficiendi corrosionem resistendi et resistendi induendi.

Sicut aes ustissimum admixtum substructio aeris formari potest in partes mittentes valde compositas, easque aptas facit ad processum obsidionem mittendum. Constans sumptus ambigua has materias pretiosissimas sensitivas efficere possunt, valde pretiosas dissipare, praesertim cum considerans CNC machinationem et/vel fabricantem ut processum fabricandi ad producendum tuum.mitte partes. Sed aes purum non solet ejicere. Aes fusuras aere mechanicas superiores habet, pretium autem aere humilius.

Aes stannum est ex cupro et zinci. Aes ex cupro et zinci vulgari aes dicitur. Si autem mixtura mixtorum ex pluribus duobus elementis constat, speciale aes dicitur. Aes est mixtura aeris cum zinco ut praecipuum. Sicut zinci contentum auget, vis et plasticitas mixturae significanter auget, at proprietates mechanicae significanter post 47% excedentes decrescent, ita zinci contentum aeris minus est quam 47%. Praeter zincum, aes fusum saepe mixtura elementa continet, ut pii, manganesum, aluminium, plumbum.

Quid aes et aes ejicimus?

- • China Latin: H96, H85, H65, HPb63-3, HPb59-1, QSn6.5-0.1, QSn7-0.2

- • USA Standard: C21000, C23000, C27000, C34500, C37710, C86500, C87600, C87400, C87800, C52100, C51100

- • European Standard: CuZn5, CuZn15, CuZn35, CuZn36Pb3, CuZn40Pb2, CuSn10P1, CuSn5ZnPb, CuSn5Zn5Pb5

| Available Metal and Alloys for different Jactio & Vestibulum Processus

| ||

| PROCESSU vestibulum | MATERIA | |

| Arena Casting | Green Arena Iactandi | Grey Iron, Ductile Ferrum, Malleabile Ferrum, Steel, Carbo Chalybe, Alloy Chalybe, Aluminium Alloy, Brass, etc. |

| Resina Coated Sand Casting | ||

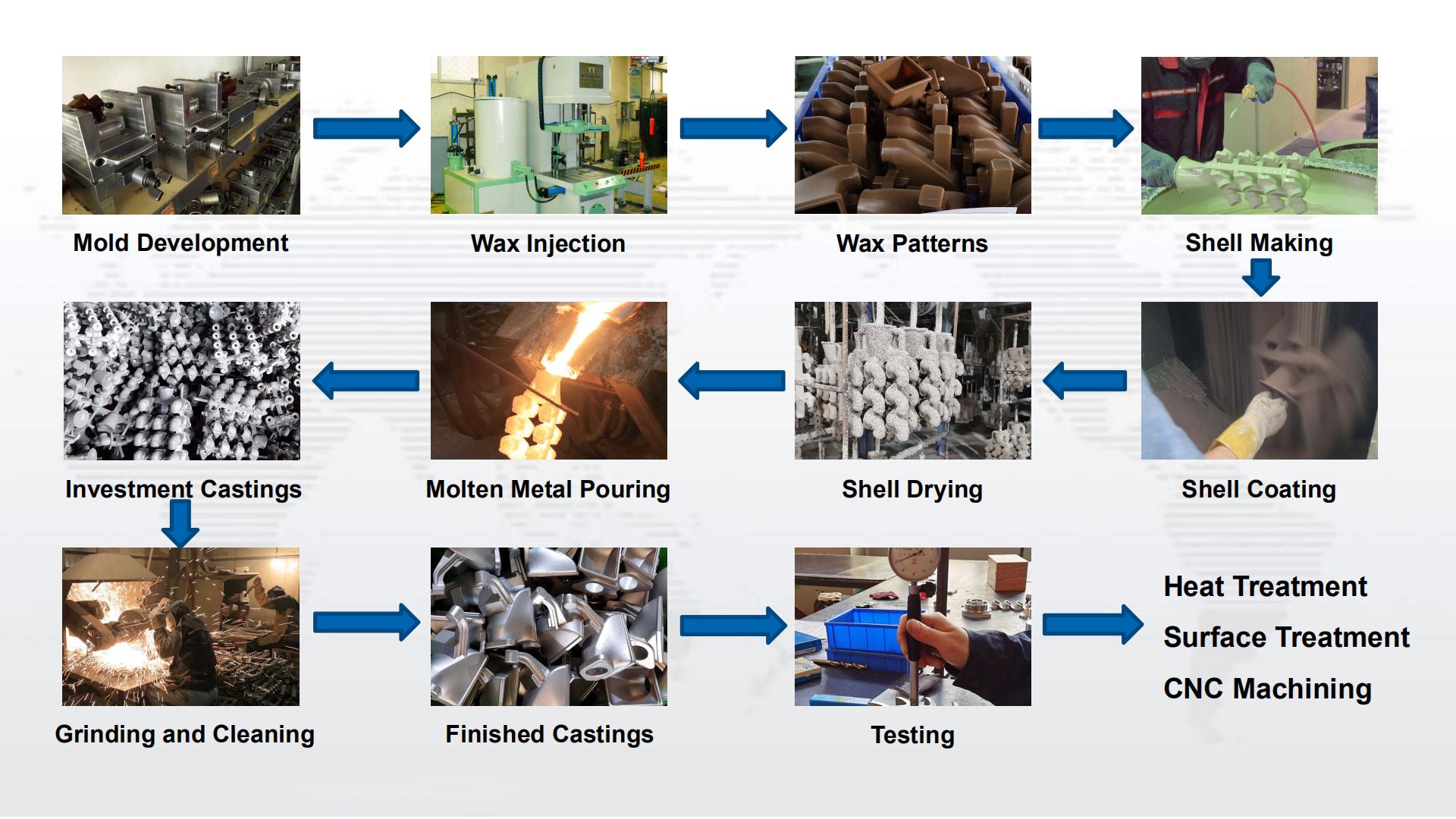

| Investment Iactare (Lost Cera Iactis) | Aquae vitreae Investment Iactantia | Carbon Steel, Alloy Steel, Diver, Duplex Steel, Ferrum, Aes, Aluminium et alia mixtura |

| Silica Sol Investment Iactandi | ||

| Lost Spuma Iactis | Ductile Ferrum / Grey Ferrum | |

| ASTM 60-40-18 / 65-45-12 / 80-55-06 / 100-70-03 | ||

| chalybeum, Hi-Mn steel, Hi-Cr steel | ||

| Austempering Ductile Ferrum (ADI) | ||

| Calor resistens Steel / gere resistens Steel | ||

| Vacuum Casting (V Process Casting) | Ferrum ductile GGG 40 ad GGG 80 / Gray Iron | |

| ASTM 60-40-18 / 65-45-12 / 80-55-06 / 100-70-03 | ||

| chalybeum, Hi-Mn steel, Hi-Cr steel | ||

| Austans ductile ferrum | ||

| Ferrum renitentem / gere resistentem ferro / Steel | ||

| Forging | Open Forging | Stainless Steel, Carbon Steel, Alloy Steel, Brass, Aluminium |

| Mori Forging | ||

| Roll Forging | ||

| Die Casting | Princeps Pressura Die Iactis | Aluminium, Zinc, Brass |

| Humilis Pressura Die Iactis | ||

| Gravitas Pressura Die fundens | ||

| Superficiem Curatio Services | Pulvis Coating, Anodization, Electrophotesis, Chrome Plating, Poesis, Sand uredine, Nickel Plating, Zinc Plating, Blacking, Polonica, Bluing, Geormet, Zintek, etc. | |

| CNC Precision Machining Services | Lathing, Milling, Convertere, Honing, EXERCITATIO, Boring, Tapping, Filum Electrode Secans, Molendum...etc. | |

| Inspectio et Qualitas Imperium | Spectrum Analyzer, CMM, Hardness Tester, Tendens robur Tester, Yild Strentgh Testor, Obsignatio Pressure Tester, Carbon Sulfur Analyser, Metallurgical Microscopia, Press Force Tester...etc. | |